-

Wheel Hub Bearings

Wheel Hub Bearings -

Wheel Hub Bearings

Wheel Hub BearingsDAC387436 DAC458045 Hub Deep Groove Ball Car Wheel Bearing

-

Spherical Bearings

Spherical BearingsFL204 FL205 FL206 Stainless Steel Pillow Block Bearing

-

Spherical Bearings

Spherical BearingsT204 T207 UC204 High Speed Insert Pillow Block Bearing

-

Spherical Bearings

Spherical BearingsFC204 F210 Auto Wheels Bike Pillow Block Bearing

-

Spherical Bearings

Spherical BearingsP207 206 205 203 High Precision Wheel Pillow Block Bearing

-

Thrust Roller Bearings

Thrust Roller BearingsS51100 S51107 S51109 Car Wheel Plain Thrust Ball Bearing

-

Thrust Roller Bearings

Thrust Roller Bearings51110 51107 51104 51206 High Speed Plain Thrust Ball Bearing

How Many Types of Motorcycle Bearings Are There?

Industry news-Motorcycle bearings factory are essential components that support the smooth operation of various moving parts, including wheels, engines, and steering systems. Bearings reduce friction, distribute loads, and provide stability to ensure safe and efficient performance.

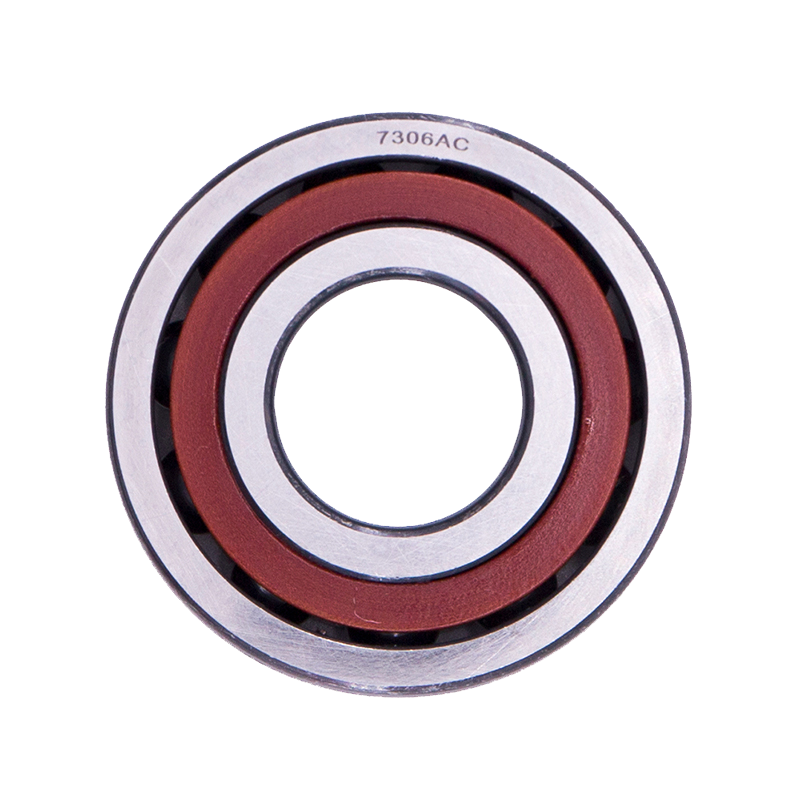

Ball Bearings

Ball bearings are one of the widely used types in motorcycles. They consist of a series of spherical balls enclosed between two races, allowing rotational movement with reduced friction. These bearings are often found in wheel hubs, steering assemblies, and engine components where radial and axial loads are present.

The main function of ball bearings is to support rotational motion while handling moderate loads. They provide smooth rotation for wheels and steering systems, contributing to ride stability and control. Ball bearings are relatively simple in design, easy to maintain, and replaceable, making them a common choice for standard motorcycle applications.

Roller Bearings

Roller bearings differ from ball bearings in that they use cylindrical rollers instead of spherical balls. This design allows them to support higher radial loads, making them suitable for parts that experience greater pressure, such as crankshafts and swing arms.

Roller bearings provide stability and load distribution under heavy stress. While they are less effective at handling axial loads compared to ball bearings, they perform well in applications where radial support is critical. These bearings are widely used in high-performance motorcycles or heavy-duty bikes that require strong and durable components to maintain reliability over time.

Tapered Roller Bearings

Tapered roller bearings are designed with conical rollers and matching races, allowing them to support both radial and axial loads simultaneously. They are commonly used in motorcycle wheel hubs and steering head assemblies, where combined load handling is necessary.

The tapered design allows the bearing to distribute stress evenly and maintain alignment under various forces. This type of bearing is particularly useful for motorcycles that carry passengers or heavy loads, as it enhances stability during cornering and braking. Regular maintenance is important to prevent wear and ensure consistent performance.

Needle Bearings

Needle bearings are a variation of roller bearings with long, thin cylindrical rollers. Their design provides a compact profile while still supporting substantial radial loads. Needle bearings are often used in motorcycle transmissions, rocker arms, and swing arms, where space is limited but reliable load support is required.

The main function of needle bearings is to allow smooth rotational movement in confined spaces without compromising load capacity. They are particularly effective in reducing friction in tight areas, which is critical for engine performance and drivetrain efficiency. Proper lubrication is necessary to prevent premature wear and maintain operational reliability.

Motorcycle bearings are crucial for the smooth and safe operation of various components, including wheels, engines, and steering systems. Ball bearings are commonly used for wheels and steering due to their ability to handle radial and axial loads. Roller bearings support heavier radial loads and are suitable for crankshafts and swing arms. Tapered roller bearings combine radial and axial load handling, making them ideal for wheel hubs and steering assemblies. Needle bearings provide compact yet strong support for transmissions and confined spaces.

English

English русский

русский Español

Español